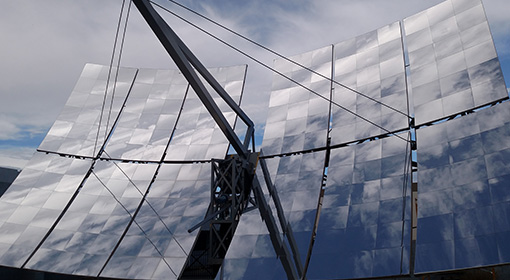

SST Thermal dish is a paraboloid dish collector with point-focus thermal fluid receiver. Compared to more common CSP (concentrating solar power systems) such as solar trough or heliostat/towers, a dish collector is the most efficient system for collecting and concentrating solar energy.

Thermal Dish Value & Efficiency:

- Highest collector-area efficiency – dish mirror area fully faces the sun at all times. Solar trough and towers suffer significant losses whenever the sun is low in the sky.

- Highest year-round efficiency due to two-axis tracking

- Compact thermal dish receiver can avoid the high convective/wind losses incurred by the long pipe used in solar trough collectors

- Solar Dish systems are much more effective in higher latitudes, where the sun is lower in the sky

- These advantages combine to deliver more year-round solar output, and higher temperatures, than solar trough or heliostat/tower systems that suffer reduced output outside of summer months

- The SST Solar dish has a collector area of about 54 square meters. During clear sky conditions a single dish can deliver about 40 kW of thermal energy, assuming nominal losses.

Advantages:

- SST Thermal systems as small as one 40 kW dish can provide high temperatures and high efficiency

- Much better suited for medium scale commercial/distributed use than troughs or towers, which typically require very large and capital-intensive projects

- Constructed using common equipment, such as forklift

- Irregular site layouts can be accommodated

- Systems can start small, with dishes added over time

- Thermal loss due to air/wind can be lower compared to long exposed pipes used in trough systems

- Pre-cast foundation, or site-built foundation

- Glass mirrors for efficiency and long life

Thermal Applications:

- Domestic hot water

- Food / Beverage processing

- Pasteurization

- Drying

- Steam Generation

- Water distillation / Membrane Distillation

Temperatures:

Solar Dish high concentration and point-focus receivers can provide heat at any temperature allowed by the thermal fluid selected.

- Pressurized water for low/medium temperatures, thermal oil for higher temperatures up to 350C

- Heat typically transferred to a heat exchanger / storage tank, for use in customer application