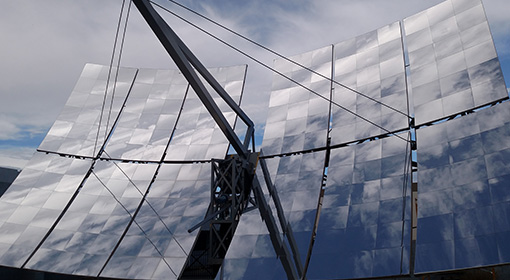

SST DISH KEY BENEFITS

- The 54 m2 Dish is a very good size for distributed market entry and utility scale use. It is large enough to be cost effective for tracking, and yet can be constructed without expensive equipment.

- Mirror shapes are precisely contoured and customized using SST design methods. This allows the light to be more efficiently delivered to CPV and thermal receivers.

- The SST Dish CPV and thermal design is a new “modularized” approach to solar power, with substantial potential for local manufacturing, and adaptation to new applications including tower systems.

FEATURES OF THE SST DISH CPV TECHNOLOGY

- The SST CPV Module operates CPV cells at 1200 suns, using secondary concentration within the module. Higher concentration lowers the CPV cell cost. As future cell efficiencies increase this added concentration helps to keep cell costs down.

- The SST Module uses standard CPV cells, made by multiple suppliers.

- The SST design places cells in parallel to allow some to run at different power levels without affecting others. Solar cells in other CPV designs are in series, so if one cell loses power or concentrated light, all in the series circuit will be impacted.

- The SST module has built in power conversion, controls and data recording, for real time operation and long term performance review.

- SST CPV module uses aluminum alloys for its heat sink, using a proprietary cooling design. This provides high efficiency at low cost.