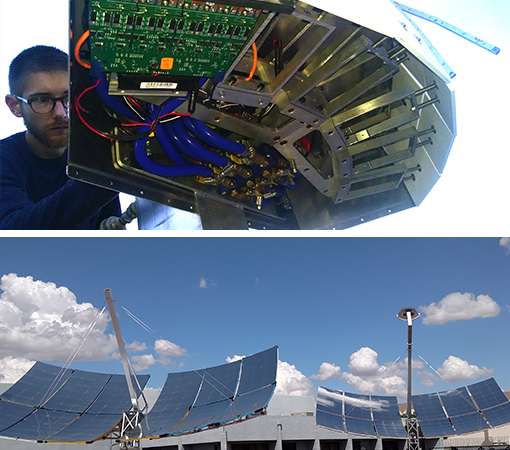

Unlike the more common CPV designs that use lenses, the SST CPV design is based on a nominal 1 kW “dense array” building block CPV module. The CPV module uses water cooling, circulated in a closed loop to a radiator like a car engine cooling system, and so it is dry-air cooled and does not consume water. This liquid cooling method provides better thermal management of CPV solar cells operating under very high concentration – over 1000 suns – and for better solar production in high temperature and harsh desert regions.

CPV MODULES FOR ELECTRIC POWER

Currently SST is able to make prototype and demonstration systems in preparation for commercial manufacturing partnerships. Target cost for this Dish-CPV product is under $2/W in high-volume manufacturing, using CPV “multi-junction” PV cell technology that is on a pathway for increasingly high efficiency. Expected CPV cell improvements over time will increase the module rating from initially 1 kW (including all system losses), to about 1.7 kW per module. These efficiency gains help to reduce the effective cost of the collector system. Two-axis tracking is used which provides for about 20-30% higher energy output than a fixed-PV system of the same rating, assuming sunny conditions, and higher annual output than solar trough or tower systems.